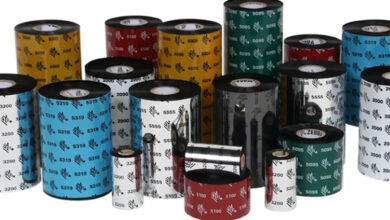

Types of Thermal Transfer Ribbons

Types of Thermal Transfer Ribbons

Thermal transfer printers are the most reliable when it comes to producing high-quality long-lasting labels. However, for the printer to function at its best you need to pick the right kind of ribbon. Here is all you need to know about thermal transfer ribbons.

Key Features of Thermal Transfer Ribbons

Thermal transfer printers use the heat generated by the print heat to melt the wax or resin-based ink on the coated side of the ribbon to impress an image, such as a barcode, on the label.

The first thing you need to check is how the ribbon is fed to your printer, that is with the coated side on the inside (CSI) or the outside (CSO). This is important as most printers can only take one style.

To reduce waste, you should choose a ribbon width that is closest to that of the label to print. Also check out the core size, since smaller printers do not have enough space to fit in a standard 1-inch core ribbon.

Now for the essential part, the various types of “ink” thermal transfer ribbons use. There are three types available: full wax, full resin, and wax-resin-coated ribbons.

Types of Thermal Transfer Ribbons – Full Wax

This is the most common type of thermal transfer ribbons. One side of the ribbon, the one that comes in contact with the printing material, is coated with ink made entirely out of wax.

During the printing process, when the label comes in front of the print head, the needles heat up and melt the wax, which is transferred to the printing material. This type of wax-based ink is recommended for use with non-coated paper.

Full wax thermal transfer ribbons are the least expensive, which makes them ideal for high-volume printing jobs. On the other hand, the labels are less durable than those produced with other types of ribbon. Still, they will last longer than labels produced with direct thermal printers.

Such ribbons are the best choice for making retail and warehouse labels, shipping labels, and shelf labels.

Types of Thermal Transfer Ribbons – Wax-Resin

This type of ribbon is coated with ink made out of a mixture of wax and resin. The labels produced using such a ribbon are more resistant than those made with 100% wax-coated ribbons.

This type of ribbon is coated with ink made out of a mixture of wax and resin. The labels produced using such a ribbon are more resistant than those made with 100% wax-coated ribbons.

The temperature needed to melt this type of ink during the printing process is higher than that needed when using wax ribbons. Wax-resin ribbons are suitable for use with various printing materials, from simple uncoated paper to coated, glossy paper, or even synthetic labels.

The quality of the printed image is better. The image will appear crisp and will not fade for a long period, even if exposed to harsh chemicals or the elements. Wax-resin thermal ribbons are recommended for both standard and weatherproof labels.

Best used for shelf labels, bin labels, barcodes, shipping labels, as well as pharmaceutical labels. This type of ribbon is a bit more expensive than wax ribbons, but the higher price makes up for the better quality of the labels.

Types of Thermal Transfer Ribbons – Resin

This is the most expensive type of thermal transfer label—it offers the highest quality. Resin-coated ribbons are used mostly for printing on synthetic materials, rather than paper.

Considering the high cost, such ribbons are only used for highly-sensitive medical and chemical labels. If what you need are standard labels, you should choose the other more affordable types of ribbons.

Types of Thermal Transfer Ribbons – Summary

Of the three main types of thermal transfer ribbons, the full wax ribbon is the most suitable for traditional labels printed on uncoated paper. The printed image is of good quality and easy to read with a scanner.

If you need very resistant weatherproof labels, choose the resin-wax ribbons. The most expensive full resin thermal transfer ribbons should only be used for sensitive labels, such as those needed in the pharmaceutical or chemical industry.

Types of Thermal Transfer Ribbons – Manufacturers

- cab Ribbons – Exclusively designed for cab printers

- inkanto by ARMOR – inkanto Thermal Transfer ribbons are approved on all Thermal Transfer printers on the market